English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

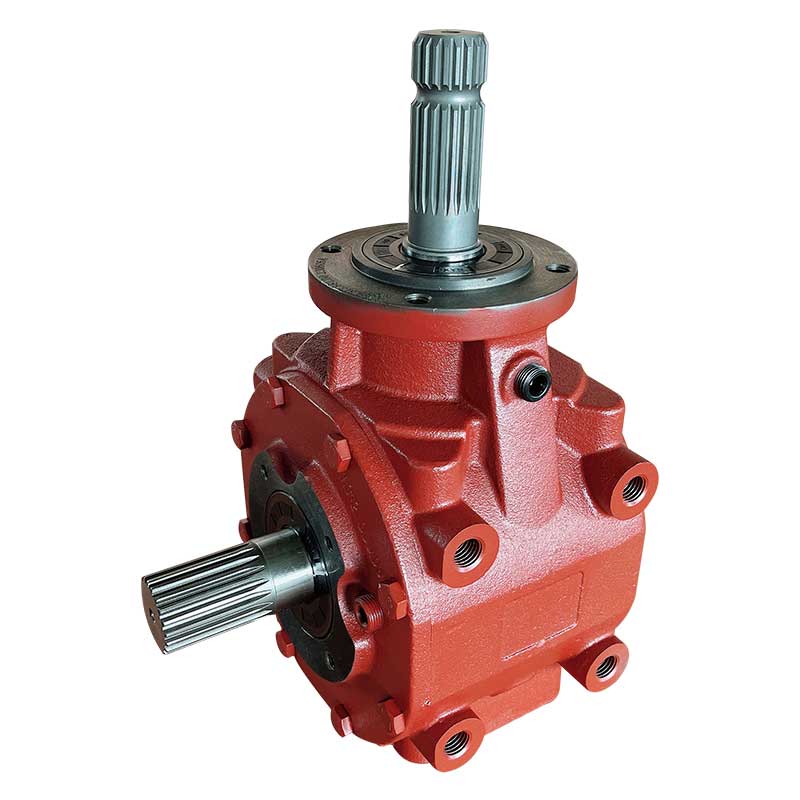

PTO Drive Shafts for Agricultural Machinery

Greetings from Minghua Gear the realm producer of PTO Drive Shafts for Agriculture Machinery ! As a China PTO shaft manufacturer, present to you a product that is renowned for its robustness, efficiency, and longevity. The requirements of our clients who work in the agricultural sectors are taken into consideration when designing and manufacturing agriculture PTO drive shafts.

Send Inquiry

Minghua Gear use strong, long-lasting materials to create our agriculture PTO drive shafts, so they can resist wear and tear. You won't need to replace them very often because they are made to last a long time.

PTO Drive Shafts for Agricultural Machinery Technical Data

|

Centre Length |

650mm |

|

Steel tube |

16Mn |

|

Shield Cover Material |

StrengthenEngineering plastic |

|

Spline End |

1-3/8-in Z6, 1-3/8-in Round Hole |

|

PTO Speed |

540rpm—1000rpm |

|

PTO Torque |

460N.m—360N.m |

|

Tractor Power |

35HP—53HP |

PTO Drive Shafts for Agricultural Machinery Features and Applications

1.High-quality PTO shafts: Compatible with a wide range of agricultural equipment, PTO shafts are strong and long-lasting.

2.Spline & Round End: Spline 1-3/8" x 6 at Tractor End. Our brush hog PTO shaft is built with a 6-spline end and has a standard size of 1 3/8". It matches flawlessly with tractors and implements of the same size and type and provides greater driving force for your equipment.

3.Compact & Safer to Use: The PTO extender shaft is a highly effective power transfer tool that is fully tested and assembled into a compact construction, making it easy to replace without any hassles.

The tractor's power is transferred to the PTO-powered attachment via the PTO (Power Take-Off) shaft. It is extensively utilized on tractor slasher, grass topper, rotary hoes, wood chippers and more.

PTO Drive Shafts for Agricultural Machinery details

1.Tractor Yoke: This kind of yoke is the first step in the PTO assembly. It is utilized to attach the driveline and is attached to the tractor. Tractor yokes come in two primary varieties. The first kind is called a Spring-Lock, and it attaches and releases the yoke using a collar that is spring-loaded. The second kind, called a Quick Disconnect, connects by a push-pin mechanism.

2.Cross and Bearing Kit: This is the u-joint that joins the PTO assembly's yokes. Either an exterior snap ring, found in the yoke's ears, or an interior snap ring situated in the bushing will be present in the cross and bearing package.

3. Shaft Yoke: This attaches the tractor yoke to the driveline shaft using a cross and bearing set.

4. Shaft: The shaft is the metal rod that connects the yoke attachments and provides the driveline's length at its center.

5. Tube: The driveline is strengthened by the shaft running inside this metal cylinder.

6. Tube Yoke: Using a second cross and bearing kit, this yoke, which is attached to the tube's end, joins the driveline to the implement.

7. Install Yoke: This links the tractor's driveline to the apparatus or item that it is maneuvering.

8. Guard: To guard against damage while in use, a strong plastic covering is positioned around the driveline.