English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

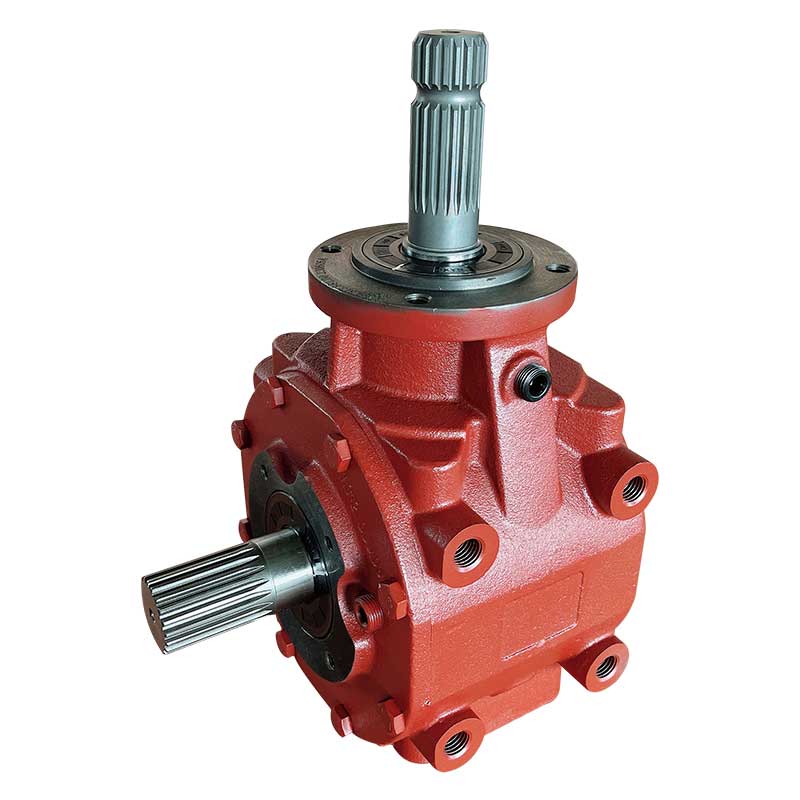

Bevel Gear Pinion for Rotary Cutter

Minghua gear manufactures Bevel Gear Pinion for Rotary Cutter with many models. Except bevel gear, we also make helical gear and spiral bevel, spur gear pinions. As a 30 years history of agriculture machine spare parts supplier we had full experience to working with you by OEM. Welcome to contact with us with any inquiry.

Send Inquiry

Minghua gear made bevel gear pinion by carbon steel.

For instance, materials like 40Cr or 20CrMnTi.

A typical steel type utilized in the production of bevel gear pinions is 20CrMnTi.

Because of its exceptional strength and longevity, this steel is a great option for industrial applications requiring dependable power transmission.

Bevel Gear Pinion for Rotary Cutter data

|

Gear teeth process |

Cutting gear or forging gear |

|

Gear teeth |

13 teeth |

|

Gear pinion material |

40Cr or 20CrMnTi. |

|

Heat treatment process |

Carburization, tempering |

|

Application |

Flail mower, grass slasher, rotary cutter…etc. |

Bevel Gear Pinion for Rotary Cutter feature

For the majority of 40 HP Rotary Cutter gearboxes, OEM input bevel gear and output pinion gear shaft.

These pinions' 20CrMnTi steel is made especially to handle the heavy loads and strains that come with rotary cutting machinery. The steel alloy becomes much more resistant to heat, wear, and corrosion when titanium is added, which is why it is the best option for this demanding application.

Bevel Gear Pinion for Rotary Cutter details

Bevel gear pinions are frequently utilized in agriculture for applications like power transfer from the engine of a tractor to the rotary cutter's blade or from the engine to the combine harvester's gearbox.

20CrMnTi steel bevel gear pinions are ideal for the demanding circumstances of agricultural labor, including exposure to dirt, moisture, and other impurities. They are a great option for machinery that is used continuously because of their resilience to wear and corrosion.