English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

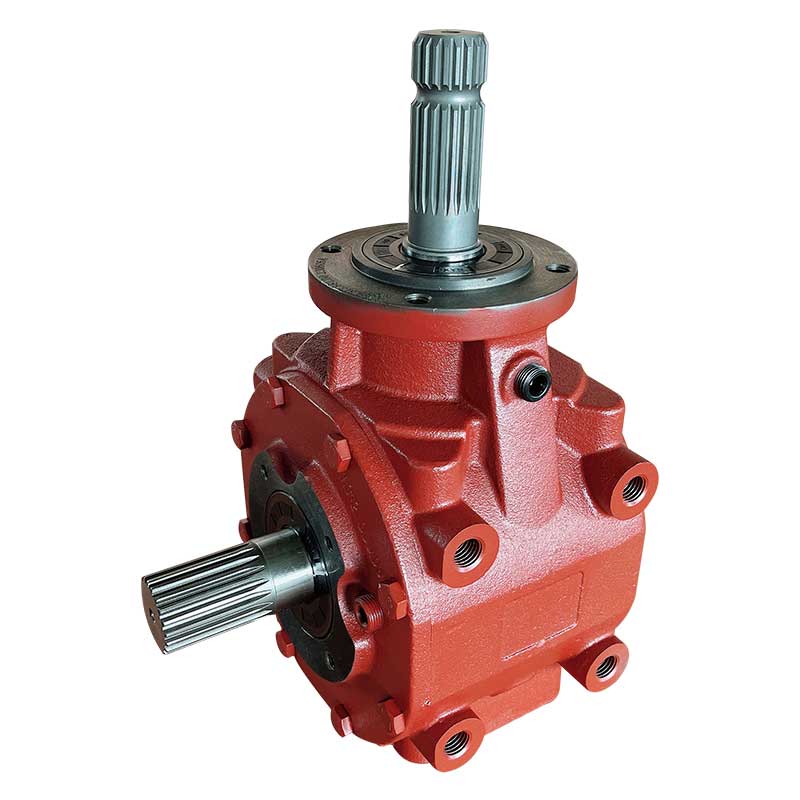

Spline Shaft for Grain Harvester

Send Inquiry

Minghua Spline shaft for grain harvester is hot sales in agriculture machines.

Because it facilitates the power transfer from the engine to the cutting and harvester components, a spline shaft is an essential component of a grain harvester. To transfer high torque stresses, the spline shaft's ridges and grooves mesh with those of other shafts or pieces of machinery.

Data Spline Shaft for Grain Harvester

|

Shaft length |

Customized |

|

Shaft material |

C45 steel, 42CrMo, 20CrMnTi, 20CrNoMi…etc. |

|

Shaft process |

Forging, turning, spline hobbing, heat treatment, grinding, cleaning, packing. |

|

Heat treatment process |

Quenching and tempering, induction, carburization, gas nitriding,…etc. |

|

Shaft application |

Grain harvester, corn harvester, differential axle shaft, rotary cutter gearbox…etc. |

|

Packing |

Durable strength wooden box for export. |

Feature Spline Shaft for Grain Harvester

Spline count: The number of teeth on the shaft is referred to as the spline count, which is an important characteristic for spline shafts. This number needs to line up with the matching part in order to guarantee proper torque transfer and meshing.

Material: Steel, alloy steel, or cast iron are the most common materials for spline shafts used in grain harvesters. These materials are selected for their strength, longevity, and resistance to corrosion and wear.

Profile: Spline shafts can have an involute or parallel profile. The torque transmission and operating speed needed for the harvester will determine which profile is best.

Details Spline Shaft for Grain Harvester

Length: The length of a spline shaft for a grain harvester will vary depending on the specific model and requirements. The spline shaft must be the correct length to provide proper alignment between components and prevent damage to the machine.

Spline count: The spline count of a spline shaft is the number of ridges or teeth on the shaft. The spline count will depend on the specific requirements of the harvester and the components that the shaft will be meshing with.

Construction: Spline shafts for grain harvesters are typically made of steel, alloy steel, or cast iron, offering high strength, durability, and ability to withstand wear or corrosion.

Diameter: The diameter of a spline shaft can vary depending on the machine's horsepower and the torque requirements. A larger diameter spline shaft may be necessary to handle higher torque loads.