English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

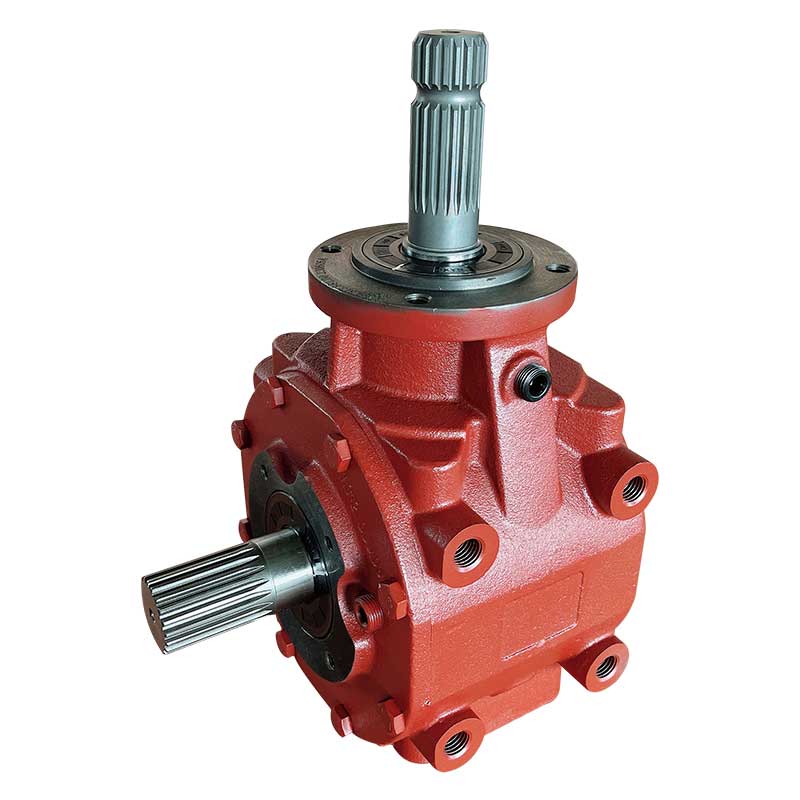

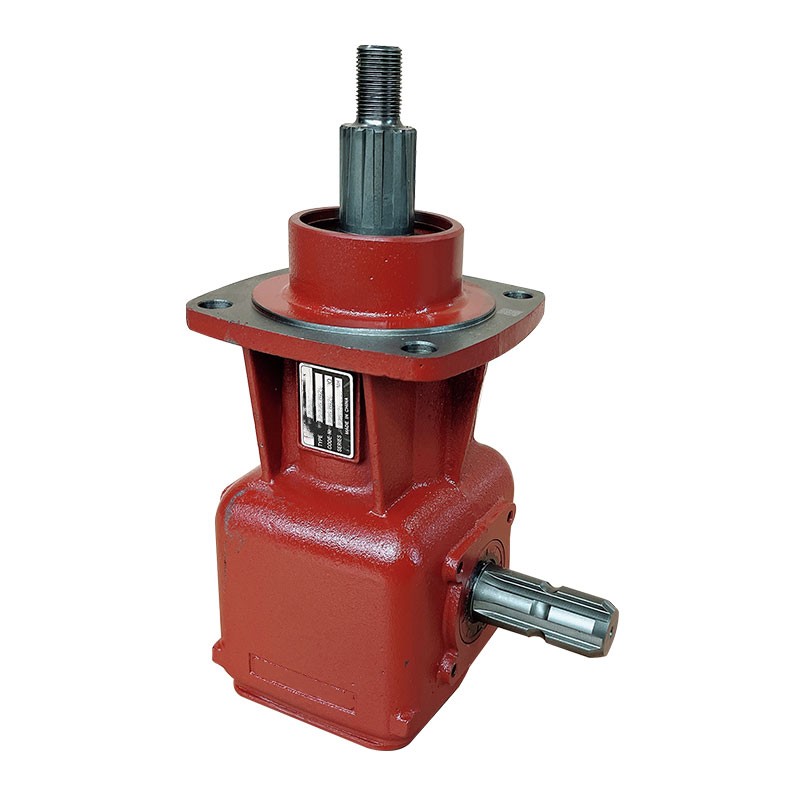

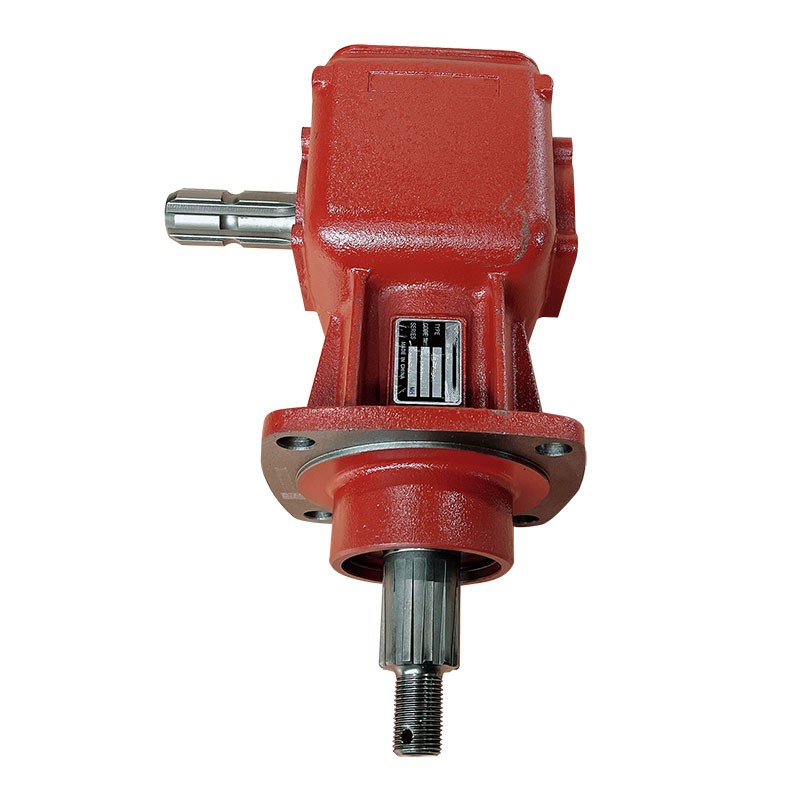

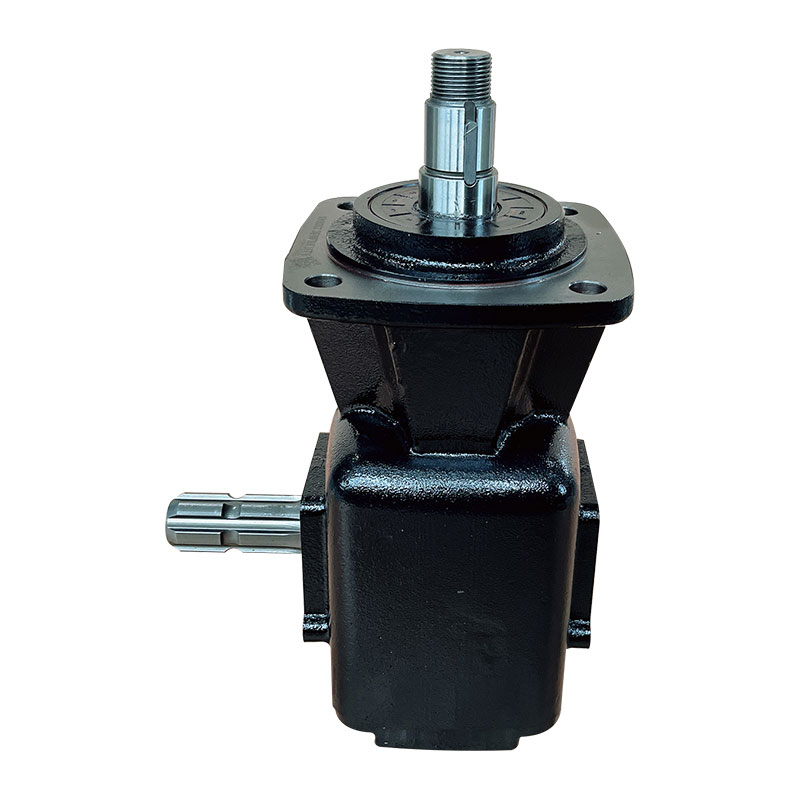

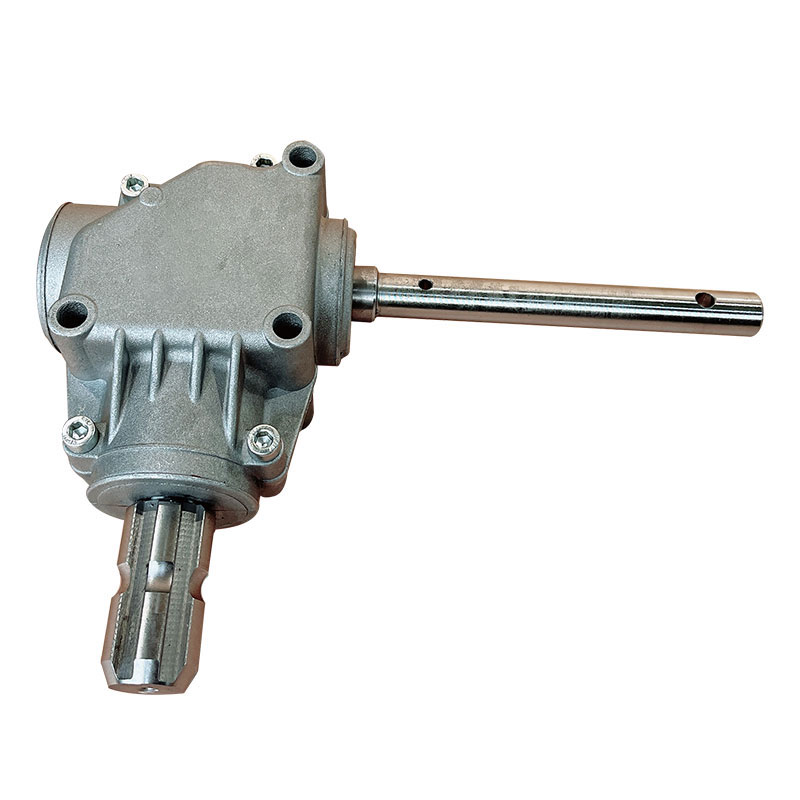

Bevel Gearboxes for Rotary Cutters

Minghua Gear is a manufacturer of replacement components for agricultural equipment and machinery, and also provides a selection of bevel gearboxes for rotary cutters. Their gearboxes are available in a range of sizes and configurations, and they are renowned for their quality and dependability. Encourage OEM customization in both design and production.

Send Inquiry

A rotary cutter bevel gearbox is a vital part of agricultural equipment. Its purpose is to transfer power from the tractor's power take-off (PTO) to the cutter's rotating blades.

The configuration can be one input shaft with one output shaft called L model gearbox.

Or one input shaft with two output shaft called T model gearbox.

Please choose as per your rotary cutter needs.

Bevel Gearboxes for Rotary Cutters data

|

Type of application |

Speed increasing unit |

|

Input power rate |

30Cv-22Kw (540RPM) |

|

Output torque |

20Nm |

|

SpeedRatio |

1:1.92 |

|

Rotation direction |

By looking "into" the moving parts (shaft, pulley, or sprocket), with the gearbox behind the component, the rotation is characterized as either clockwise or counterclockwise. |

|

Net weight |

17.6Kg |

Horsepower: 75

*For 5 ft, 6 ft rotary cutters

*Outside rotation: clockwise or counterclockwise with no modifications

*Housing construction: Ductile iron

*21 splines input shaft: 1-3/8 in.

*Output shaft 2 in. 15 Spline

*Gear type: Bevel gear

*Bolt pattern: (4) 3/4" diameter holes on a 8 in. bolt circle

*Gear ratio: 1:1.71

*Input Shaft centre to the base flange is 7.06"

*Output shaft length from the base flange is 7.85"

*Shipped dry, please add 16OZ 80-90W gear lube before using

*Weight: 75lbs

Bevel Gearboxes for Rotary Cutters features and applications

Durability: The high-quality materials used to make the rotary cutter gearbox, such as hardened steel, provide long-lasting performance.

Gear ratio: Depending on the rotary cutter's size and intended use, a rotary cutter gearbox's gear ratio usually ranges from 1:1.46 to 1:1.93.

Power input: Depending on the size and use of the rotary cutter, the gearbox can have an input power of 15–250 HP.

Output shaft: The gearbox produces the power needed to rotate the blades using a single output shaft design.

Application of rotary cutter gearboxes.

Lawn care machines, forestry machines, landscaping machines and related agriculture machines.

Bevel Gearboxes for Rotary Cutters details

Gearboxes for rotary cutters are a crucial part of agricultural equipment that is used to cut and remove dense growth.

The housing use ductile iron and formed by foundry process.

The gears use forging process to keep the completely metallographic structure.

The gears and pinions will be heat treated by in house control.

Before shipping, a 100% leak test is performed on the gearbox.

Single output or double output shaft configuration is available for choose.

Painting color can be selected as per client’s requirement.