English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

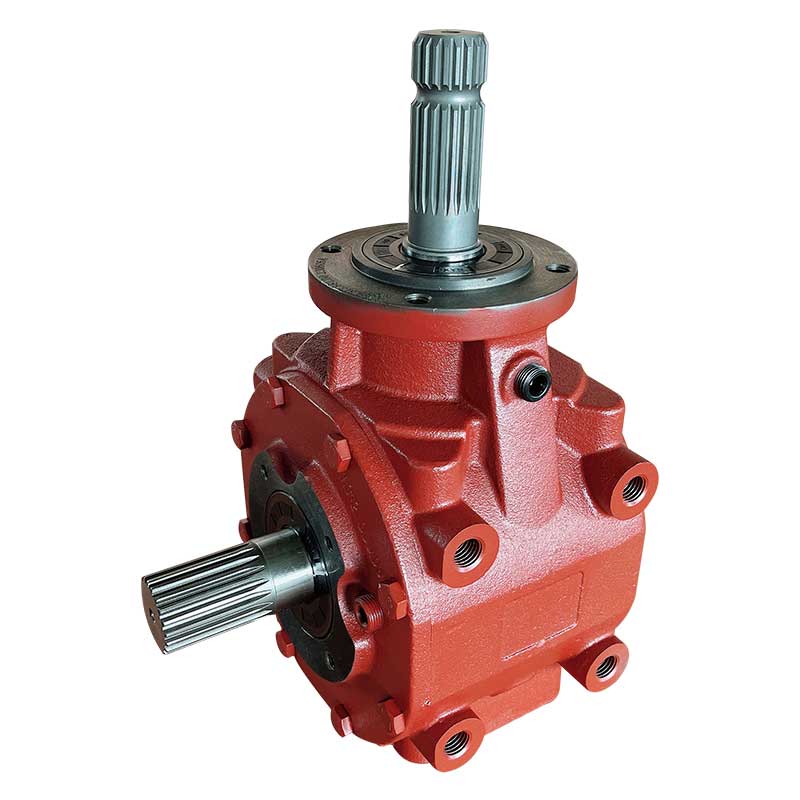

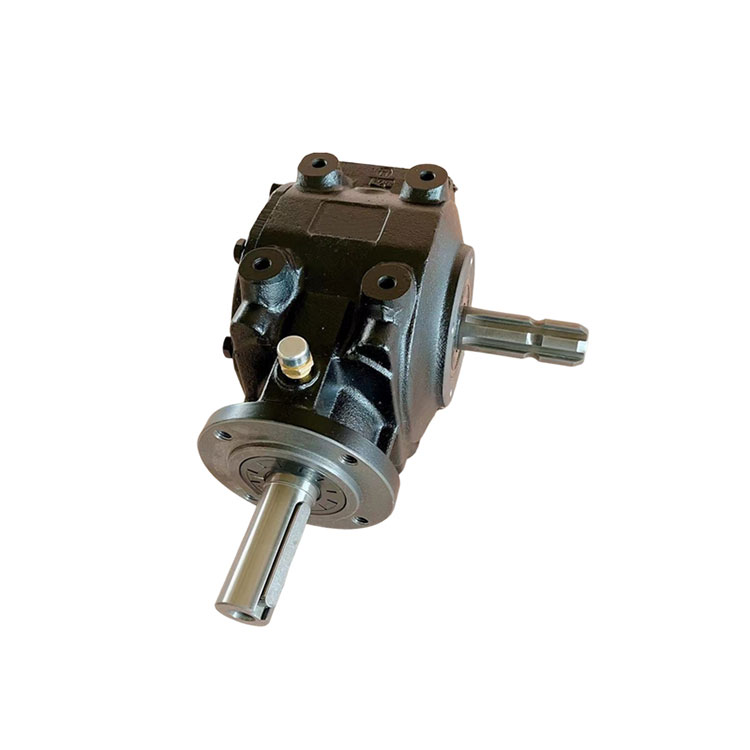

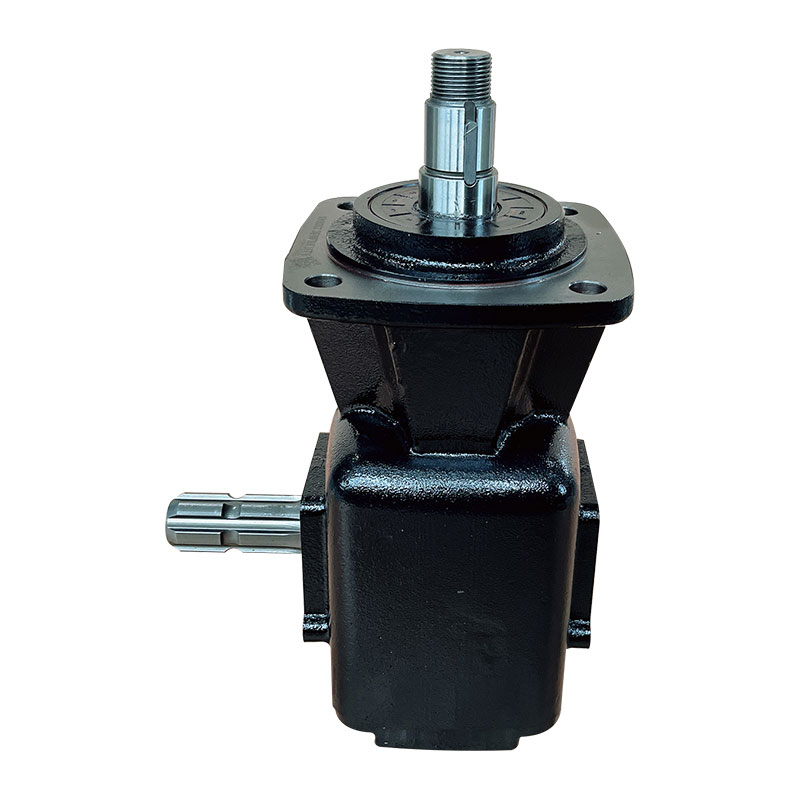

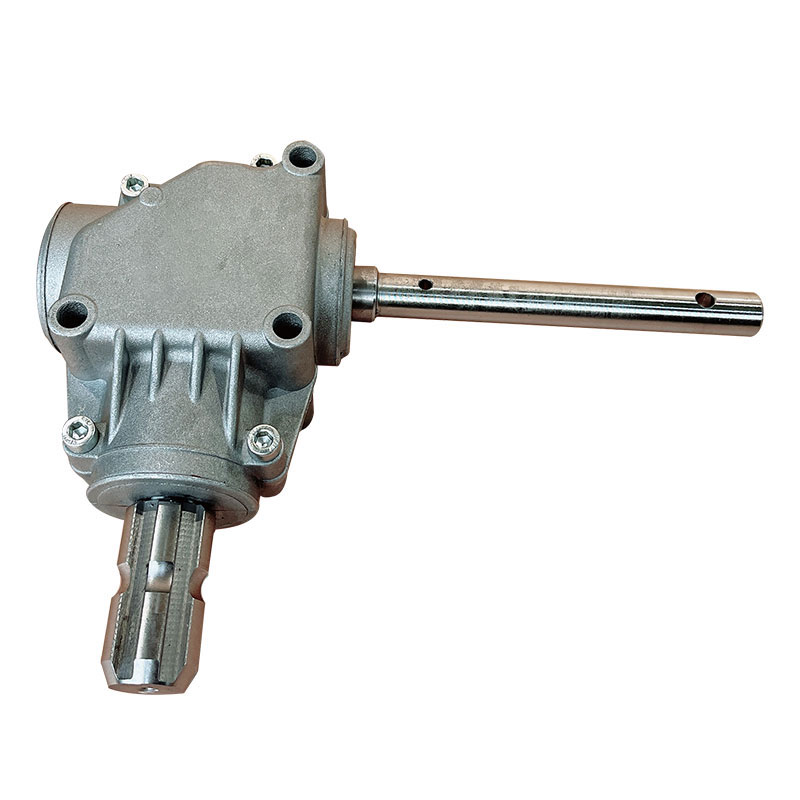

Flail Verge Mowers Gearbox

Send Inquiry

Flail Verge Mowers Gearbox

Flail verge mowers gearbox plays a crucial role in the functionality of flail verge mowers, which are used for cutting and maintaining vegetation along roadsides, embankments, ditches, and other hard-to-reach areas. The gearbox is responsible for transmitting power from the mower's engine to the flail cutting mechanism, converting rotational motion into the necessary cutting action.

Flail verge Mowers gearbox data

|

Type of application |

Speed increasing unit |

|

Gear ratio |

3:1 |

|

Input speed |

540rpm |

|

Gearbox housing |

Ductile iron |

|

Input shaft |

6 teeth 1 3/8 spline shaft |

|

Output shaft |

Plain axis withkeyway |

|

Input power |

50Cv-36.8kw |

|

Weight |

23.2Kg |

|

Configuration |

Overrunning clutch available. |

|

Note |

Ship without oil |

Flail verge Mowers gearbox feature and application

Durability: Since flail verge mowers often operate in rugged environments and encounter tough vegetation, the gearbox must be built to withstand continuous use and potential impacts.

High torque capacity: The gearbox should be capable of handling high torque loads generated during the cutting process without sacrificing performance or risking damage.

Efficiency: A well-designed gearbox minimizes energy loss during power transmission, ensuring that the mower operates efficiently and effectively.

Flail verge Mowers gearbox details

The construction of a flail verge mower gearbox involves several key components that work together to transmit power from the mower's engine to the cutting mechanism. Here's a detailed overview of the typical construction of such a gearbox:

Housing: The gearbox housing serves as the outer casing that encloses and protects the internal components. It is typically made from sturdy materials such as cast iron or aluminum alloy to withstand the stresses and impacts encountered during operation.

Input Shaft: The input shaft receives rotational power from the mower's engine or power take-off (PTO) system. It is connected to the gearbox's input gear, which initiates the power transmission process.

Gears: Inside the gearbox housing, a set of gears are arranged to transmit power from the input shaft to the output shaft. These gears may include spur gears, helical gears, or bevel gears, depending on the specific design of the gearbox. Gear ratios are carefully selected to optimize torque and speed for efficient cutting performance.

Output Shaft: The output shaft transfers power from the gearbox to the flail cutting mechanism. It is connected to the gearbox's output gear, which rotates at the desired speed to drive the flail blades or hammers.

Bearings: Bearings support and guide the rotating shafts and gears within the gearbox, reducing friction and wear. They are typically ball bearings or roller bearings designed to withstand radial and axial loads.

Seals and Gaskets: Seals and gaskets prevent lubricant leakage and ingress of contaminants into the gearbox, ensuring smooth operation and prolonging the lifespan of internal components.

Lubrication System: A lubrication system delivers oil or grease to the gearbox's moving parts, reducing friction, dissipating heat, and preventing premature wear and failure. Some gearboxes may have integrated oil reservoirs and pumps, while others rely on manual lubrication or external systems.

Keywords.

Cast Iron Flail Mower Gearbox

Heat-Treated Gears for Flail Mowers

Sealed Gearbox for Dusty Environments

Low RPM High Torque Flail Mower Gearbox

Weather-Resistant Verge Mower Gearbox

ISO-Certified Flail Mower Gear Drive

Long-Lasting Flail Mower Gearbox

Low Maintenance Gearbox for Verge Mowers

Overload Protection Flail Mower Gearbox

Quiet Gearbox for Municipal Mowing

Gearbox Repair for Flail Verge Mowers

Product video