English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

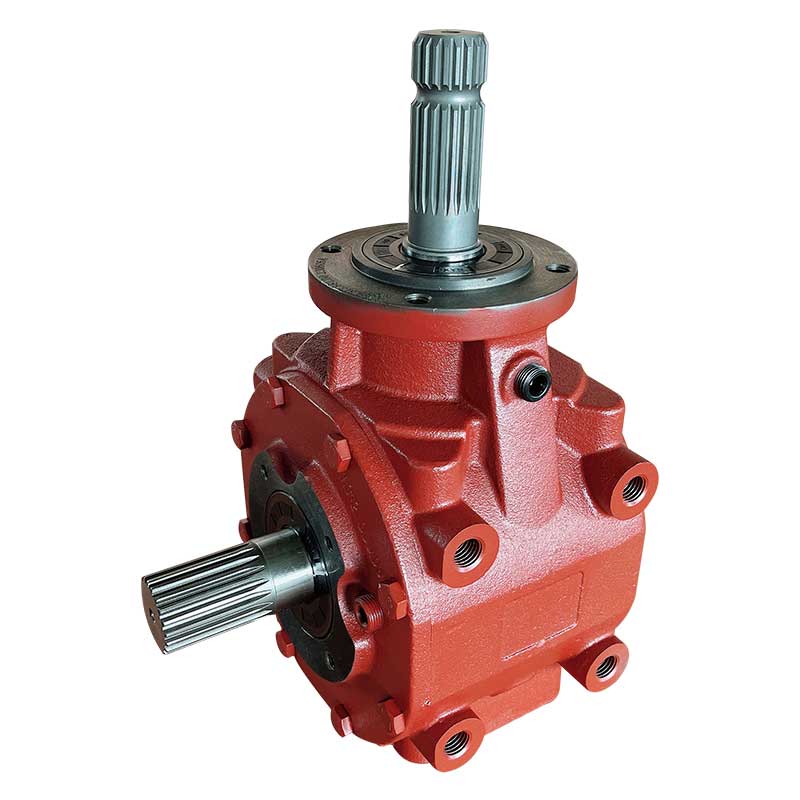

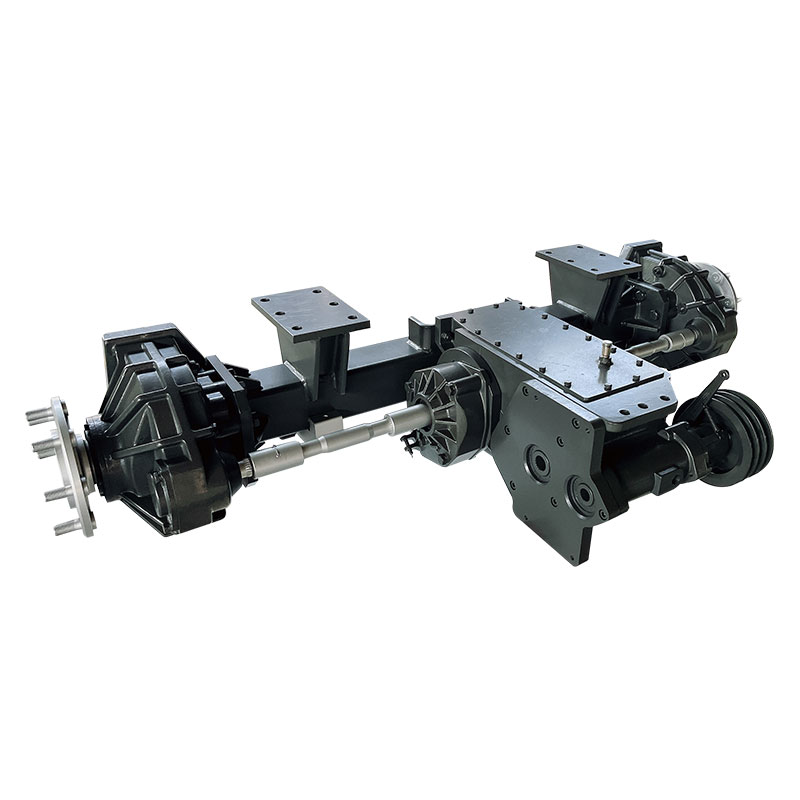

Rear Axles for Combine Harvesters

Minghua Gear manufactures a variety of rear axles for combine harvesters. Such as high-capacity axles appropriate for heavy-duty harvesting, those are tailored to the unique requirements of combine harvesters. Our factory is known for creating rear axles of the highest caliber that are dependable, effective, and long-lasting.

Send Inquiry

Rear axles for Combine Harvesters are essential parts of agriculture machine.Because they transfer power from the engine and gearbox to the wheels.

They are crucial in making it easier to travel around the field and in offering superior steering and control.

Rear Axles for Combine Harvesters data

|

Gear shift range |

Stage I |

Stage II |

Stage III |

Stage R |

|

Speed ratio |

22.644 |

9.403 |

3.747 |

10.536 |

|

Clutch type |

Diaphragm spring clutch |

|||

|

Application |

Wheat and corn combine harvester |

|||

|

Max input torque |

350N.m(255mm),436N.m(275mm) |

|||

|

Apply machine loading |

10 tons and below |

|||

Rear Axles for Combine Harvesters feature and application

(1) Changing from sliding gear shifting to meshing sleeve gear shifting reduces shifting impact and noise, makes shifting light and flexible.

(2) Referencing car gear shifting mechanisms, using soft shaft shifting and top cover shifting to facilitate gear shifting lightweight and flexible gear selection.

(3) Adopting a large capacity diaphragm spring clutch with high input torque.

(4) Strengthening the first and half shafts to improve the reliability of the drive axle assembly;

(5) This drive axle can be equipped with a clutch that can be cancelled and an HST structure added, greatly improving the reliability of the entire machine and increasing the efficiency of the harvester by about 30%.

Numerous types of vehicles, such as cars, lorries, buses, construction equipment, and agricultural machinery, employ rear drive axles. A rear drive axle's main function is to transfer power from the transmission to the wheels so that the car may move forward.

Rear Axles for Combine Harvesters details

Use all contact gear shift mechanism to extend use life.

Cancel clutch broaden the HST(static hydraulic)drive axle constructors.

Housing axle body machined by horizontal CNC to make stronger reliability.