English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

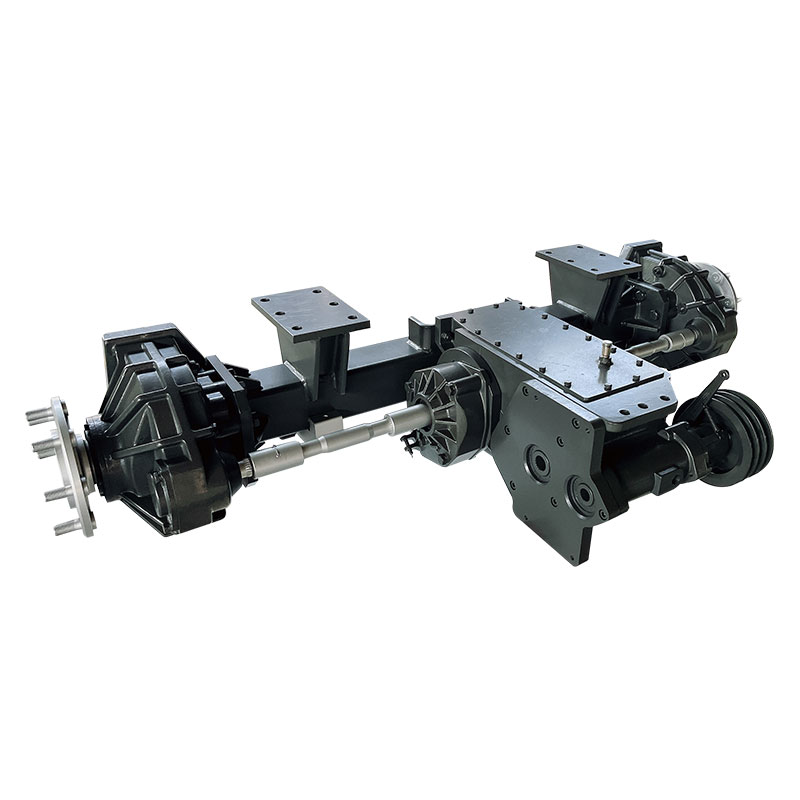

Transmission Assembly Axle for Harvester Tractor

Send Inquiry

Minghua gear made Transmission Assembly Axle for Harvester Tractor is our patent product.It uses the integrated structure to make the steady of whole axle.Also it’s a quick and easy maintenance part.

Transmission Assembly Axle for Harvester Tractor data

|

Type |

Meshing Sleeve Type |

|

Input torque |

255 N.m |

|

Output torque |

4150 N.m |

|

Gear oil capacity |

20L |

|

Gear ratio |

1st gear 32.7496, 2nd gear 25.2534,3rdgear 17.5932 |

|

Match main motor power |

100-120Hp |

Transmission Assembly Axle for Harvester Tractor features

(1) The bridge housing adopts an integral structure, a widened shell, and QT material; Strengthen the structural design of gears and shafts to increase product reliability and wider adaptability;

(2) The wet friction plate adopts imported enlarged friction plates, greatly improving the service life of the assembly friction plate;

(3) Strengthen the strength of the half shaft, half shaft sleeve, and sprocket. The connection between the half shaft and sprocket adopts a tapered spline structure, greatly improving the reliability and service life of the product.

(4) The high-speed gear adopts a grinding process to optimize the shifting mechanism structure, thereby reducing the noise of the drive axle assembly and making the shifting performance more lightweight, flexible, and reliable.

(5) Optimize the internal structure, focus on strict control of key points, and use horizontal machining centers to process key parts (such as the shell and front axle beam). Ensure that the reliability of the assembly remains at the forefront of the industry.

Tractors, combines, harvesters, and other equipment utilized in the agricultural harvest season are examples of machinery that frequently uses transmission assembly axles.

Transmission Assembly Axle for Harvester Tractor detail

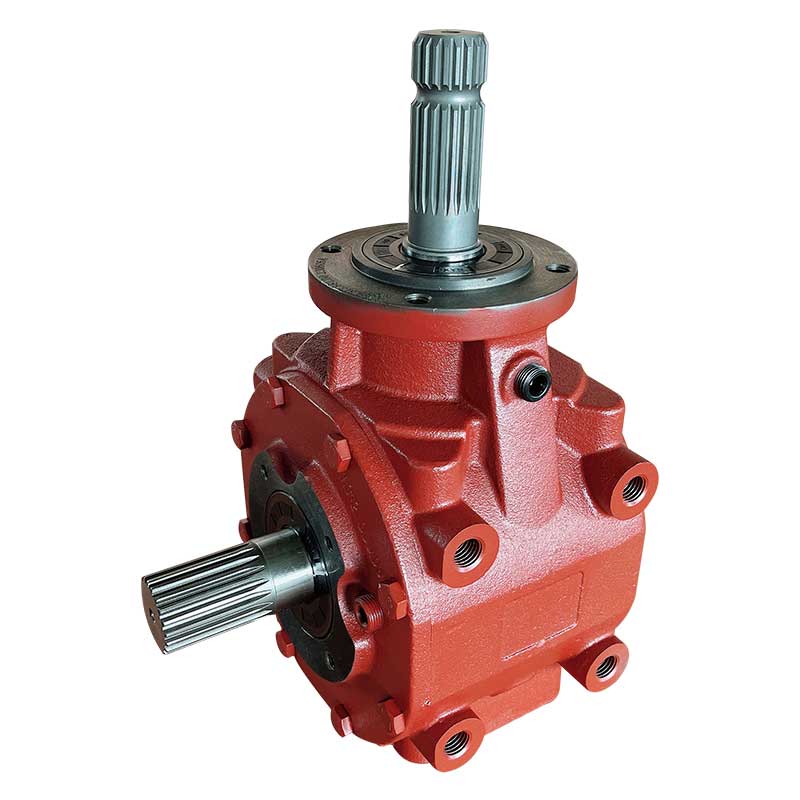

Gearbox has the advantages of large output power, strong bearing capacity, flexible and reliable steering braking, simple operation, strong adaptability to the environment, and is suitable for all kinds of large and medium-sized combine harvesters, tracked transport vehicles and rotary cultivators.