English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

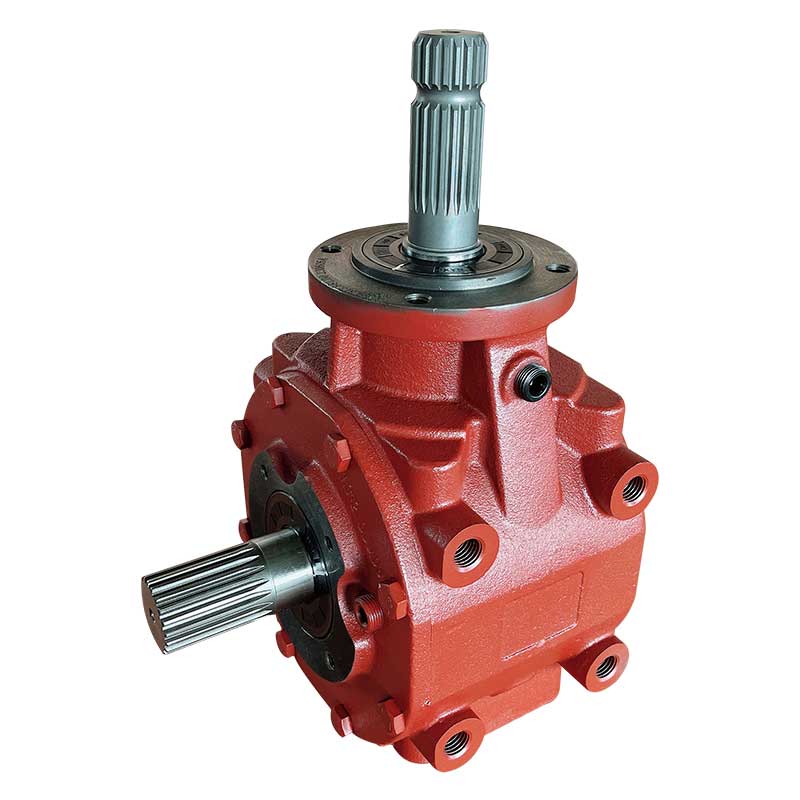

Gear Shaft for Excavator

Minghua gear manufacture a wide range of gear shaft for excavators, along with planetary gears, swing gears, and final drive gears. With over thirty years of expertise, has cooperated with original equipment manufacturers with OEM supplies. To discuss your task, please contact our knowledgeable staff at any time.

Send Inquiry

Minghua gear shaft for excavator is widely used on construction machines.An excavator's gear shaft is an essential part that helps with power transmission and permits the machine's many movements and operations.

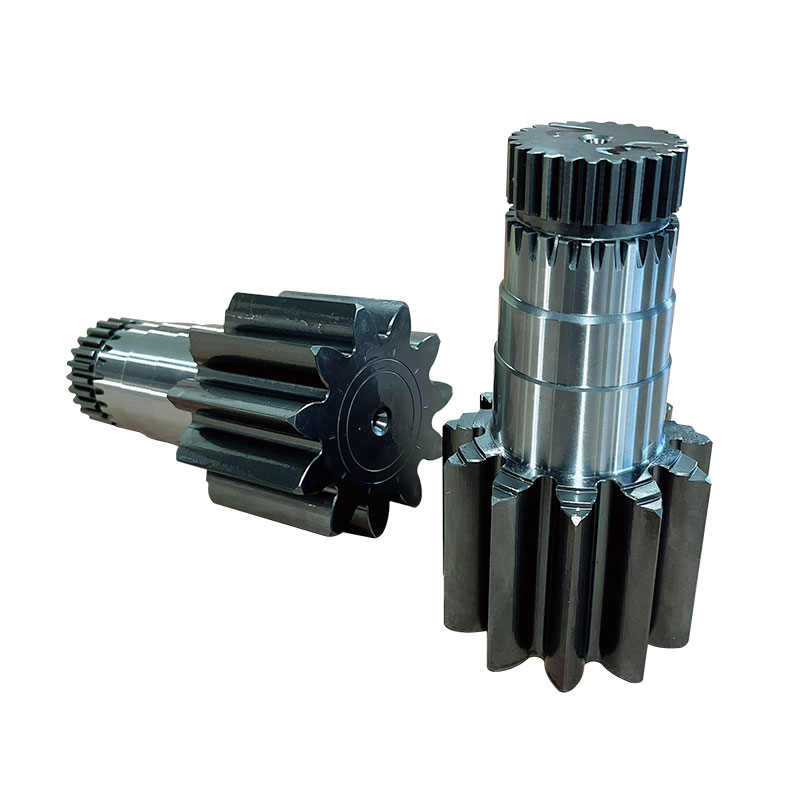

Many different kinds of construction equipment frequently use a swing gear pinion shaft. An industry engine, gasoline, a generator set, a rotary drilling rig (foundation drill), a track-type tractor, and a hydraulic excavator are a few examples.

Gear Shaft for Excavator data

|

Gearing Arrangement |

Shaft gear |

|

Product name |

Swing Drive Shaft |

|

Material |

20CrMo, 40CrMo,42CrMo,20MnCr5…etc. |

|

Heat treatment |

Carburization, gas nit riding, tempering, induction…etc. |

|

Gear machining |

Hobbing, shaping, shaving, broaching, grinding …etc. |

|

Application |

Construction machine spare parts, excavator transmission part. |

Gear Shaft for Excavator feature and applications

Power Transmission: The excavator's gear shaft is essential in transferring power from the engine to its various parts. It facilitates the transfer of rotational energy and torque to power necessary operations.

Gear Shaft Types:

The main shaft serves as the main link between the engine and the transmission system. It is in charge of transferring engine power to the excavator's other gear systems.

Counter Shaft: The counter shaft assists in distributing power to the machine's various components by cooperating with the main shaft. It is an essential part of the entire transmission system and may have several gears.

Composition and Materials:

High-strength alloy steels are usually used to make gear shafts in order to withstand the heavy loads and stresses that come with operating an excavator.

For optimal performance and precise gear engagement, precision machining is essential.

Gear Shaft for Excavator details

Mechanism of Gearing:

Excavators frequently use gear shafts with a system of gears of differing sizes to regulate the torque and speed of various operations. Excavator operations are made more versatile by this gearing mechanism.

Control and Motion:

The boom, arm, and bucket of an excavator are among the parts whose movements are managed by the gear shaft. Precise manipulation of these movements is made possible by varying gear ratios and configurations.

Upkeep and Greasing:

To guarantee that the gear shaft is operating properly, regular maintenance is required. This could entail performing wear and tear inspections, lubricating moving parts, and fixing any problems that might impair functionality.

Hydraulics Integration:

The gear shaft in contemporary excavators functions with hydraulic systems to regulate different movements. The operations of the excavator can be precisely and efficiently controlled thanks to this integration.