English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

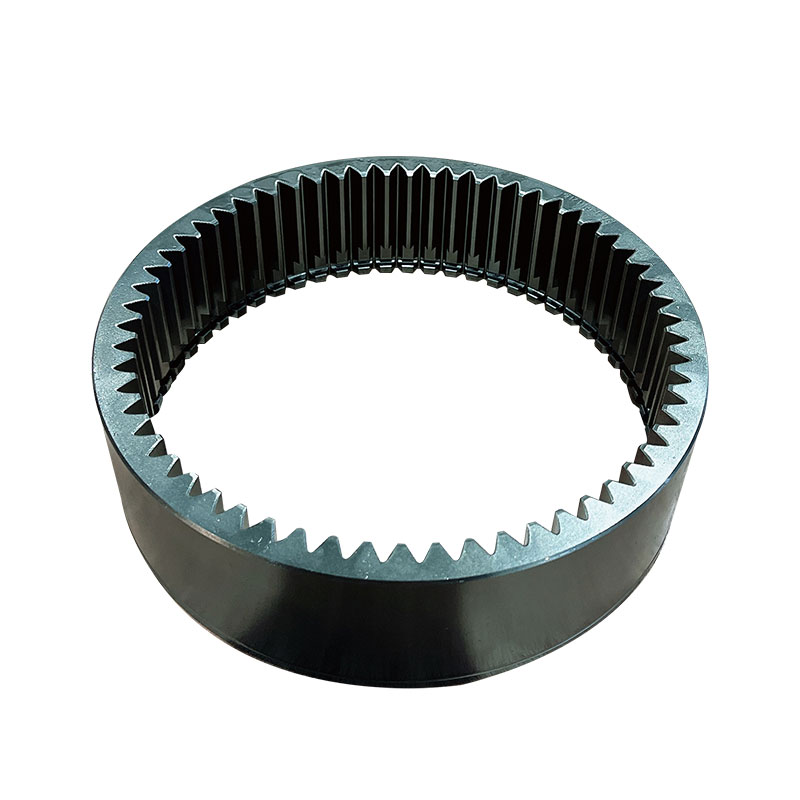

Ring Gear for Construction Machine

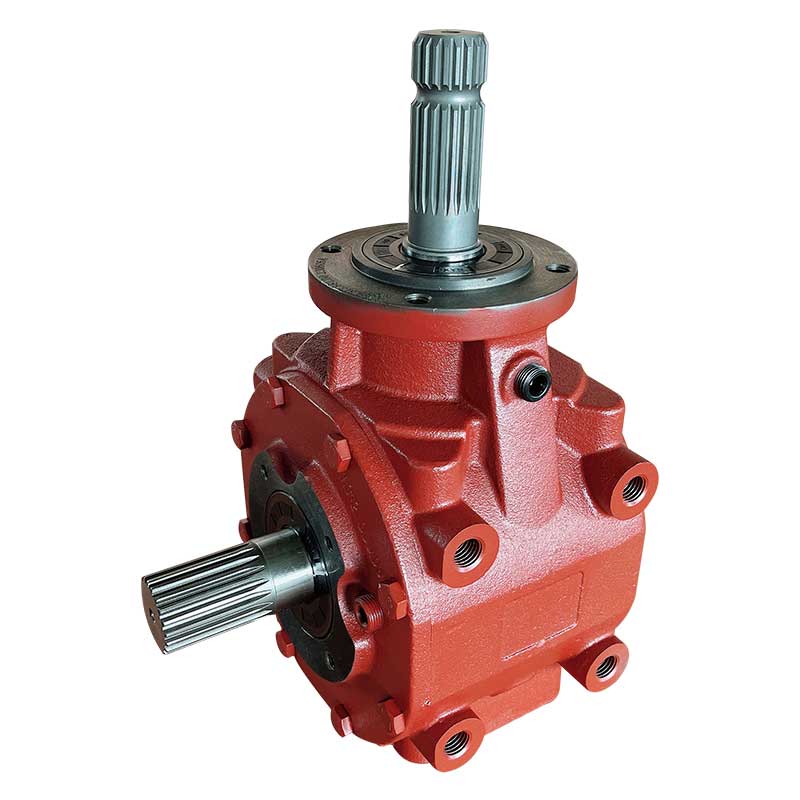

Minghua gear is a precise manufacturer of Ring Gear for Construction Machines. In addition to the manufacturer, we also integrate R&D, production, and sales. Our primary products include transmission gears, precision planetary gearbox gears, engineering equipment gears, power tool gears, precision oil pump gears, precision machine tool gears, and other high-quality transmission gears.

Send Inquiry

Minghua Ring Gear for Construction Machines is widely chosen by client.A gear with teeth on the inside surface of a cylindrical ring is called an internal gear ring.A smaller pinion gear, housed inside the ring, meshes with the teeth of an internal gear.

Ring Gear for Construction Machines data

|

Gear Model |

Internal Gear |

|

Material for selection |

40Cr,42CrMo,18CrNiMo-6,20MnCr5…etc. |

|

Processing |

Gear hobbing, gear shaping, gear shaving, gear milling, tooth grinding…etc. |

|

Heat treatment |

Tempering and quenching, Nitriding…etc. |

|

Surface Treatment |

Black oxide, sandblasting, phosphatizing, galvanizing, or according to your specifications. |

|

Application |

Hub reduction; automobile; construction machinery |

Ring Gear for Construction Machines feature

Based on the differences in the gear tooth profiles, internal gears can be classified as spur or helical.It is essential for transferring engine power to the machine's axles, wheels, or tracks.

To guarantee correct synchronization with the pinion gear, which is normally coupled to the machine's drive shaft, the ring gear's teeth must be machined exactly.

The majority of applications for internal ring gears are in the bulldozers, excavators, and cranes.Also used on automotive at transmission, wind power, truck hub reduction, and industrial gear reducer industries.

Ring Gear for Construction Machines details

Different configurations of internal ring gears, including planetary gears, rotatable gears, and fixed gears, are possible. Internal ring gears have a versatile design that makes them appropriate for a multitude of uses, including industrial pumps, transportation systems, and construction equipment.

Keywords for ring gear used on construction machine.

Planetary ring gear: Found in planetary gear systems.

Excavator ring gear: Specific to excavators.

Backhoe ring gear: Specific to backhoes.

Bulldozer ring gear: Specific to bulldozers.

Loader ring gear: Specific to loaders.