English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

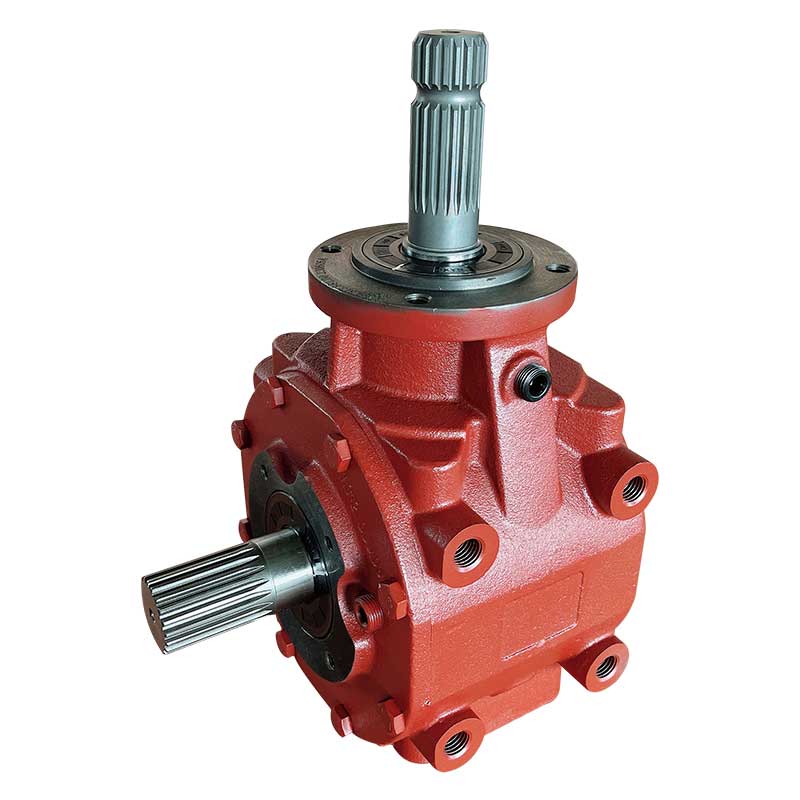

Spur Gears for Planetary Reducer

To satisfy a variety of client needs, Minghua Gear produces spur gears for Planetary Reducer in a range of module sizes, materials, tooth profiles, and other parameters. As a reliable supplier, we can offer top-notch goods, prompt delivery, and technical assistance.

Send Inquiry

Minghua gear made Spur Gears for Planetary Reducer employed as the driving and driven gears. To transfer torque and power through the planetary gear set, the spur gears cooperate with the planetary gears, sun gear, and ring gear.

Multiple planetary gears, or "planets," which are mounted on a carrier that revolves around a central axis, mesh with the sun gear.

Spur Gears for Planetary Reducer data

|

Modular |

M4,M6,M8 |

|

Ratio |

As per requirement |

|

Teeth process |

Hobbing,shaping,shaving,grinding |

|

Material |

20CrMnTi, 20CrMo, 40CrMo, …etc. |

|

Heat treatment |

Temper and quench, Carburization, nitriding…etc. |

|

Application |

Excavator, crane, loader…etc. construction machine. |

Spur Gears for Planetary Reducer feature &application

Spur gears are a kind of straightforward and effective gear that function effectively in many different mechanical systems. The exact application requirements as well as elements like torque transmission, efficiency, speed, and noise level will determine which spur gears are best.

Automotive transmissions frequently employ spur gears to supply the vehicle's wheels with the power and torque they require.

Industrial Machinery: Conveyors, pumps, and machine tools are just a few of the many pieces of machinery that use spur gears. They frequently supply a lot of torque at slow speeds.

Spur Gears for Planetary Reducer details

A planetary reducer's spur gears need to be carefully chosen in order to provide effective power transmission and a long lifespan. Here are some specifics about the spur gears that are utilized in planetary reducers.

Tooth Profile, Pressure Angle, Pitch Diameter…etc.

The choice of spur gear is contingent upon several aspects pertaining to the particular application, as well as the overall gear system design and other relevant components.